Characteristics of Nanyishan Fractured Reservoir and Productivity in Chaidamu Basin, in the Western China

Zhongchun Li1, Chengzhang Wei2, Cairu Wei2, and Xiongzhi Liu2

Institute of Petroleum Exploration & Development-Northwest of PetroChina, Lanzhou, China ([email protected])

Abstract

Nanyishan E32 fractured reservoir in Chaidamu Basin of China has the common characteristics of fractured reservoirs and is also unique at genesis, lithology, identification, distribution, and productivity. The reservoir is a mixture of carbonate rock, calcareous mudstone, and clastic rock. The coarse particles mingle with the fine ones and there is no single and pure rock type. There are high-angle fractures, oblique fractures, and horizontal fractures in this kind of fractured reservoir, which are fine and dense and connected with each other perfectly, supplying the key space for oil and gas accumulation and transportation. From the two limbs to the crest, the reservoir distributes relatively uniformly and the lithology is steady, having a feature of stable inland lacustrine deposit facies. The drainage pressure and the saturation mid-value pressure of the reservoir interval are 1.30~8.06 MPa and 3.12~10.22 MPa, respectively. In the non-reservoir interval, the drainage pressure is usually larger than 30 MPa and the saturation mid-value pressure is 80~124 MPa, which are larger than those of the reservoir interval. In the reservoir interval, circulation loss and well blowout occurred nearly in all wells during well drilling process. There were two distinct phenomena of cycle skip in SDT curves and wellhole enlargement in caliper curves, respectively. The reservoir interval also had electric logging characteristics of clasolite reservoir, such as negative anomaly of SP. Gas well productivity by natural energy was relatively low, and the low permeability was the main reason

1. Introduction

Nanyishan structure is located in the northwest part of Chaidamu Basin in China, which is a long axis anticline with nearly NW-SE strike. Research indicates that Nanyishan E32 fractured reservoir has the common characteristics of fractured reservoirs, and is also unique at genesis, lithology, being identified, distribution, and productivity. The reservoir is a mixture of carbonate rock, calcareous mudstone, and clastic rock. The fractures supply the main reservoir space and flowing passageway for the hydrocarbon. The drainage pressure and the saturation mid-value pressure of the reservoir bed are relatively low, but they are relatively high in the non-reservoir intervals. During the well drilling process, circulation loss or well blowout occurred nearly in all wells when the reservoir bed was encountered. There were two distinct phenomena, i.e., cycle skip shown in SDT logs and borehole enlargement presented in caliper curves. The reservoir bed also has electric logging characteristics of clasolite reservoir, e.g., negative anomaly of SP. Gas well productivity by natural energy drive is relatively low, the main reason for which is the low permeability.

2. Reservoir characteristics

2.1 Reservoir lithology

Grey or dark grey carbonate rock predominates in the reservoir bed and calcareous mudstone takes the second place. Besides, there is a sort of clastic rock. The reservoir is featured with interstratified layers.

Nanyishan middle-deep reservoir is characterized with dry inland lacustrine deposit facies of Chaidamu Basin. In structure, the coarse particles are mingled with the fine ones. In composition, the rock contains several mineral components. So, it can be called “diamictic phenomena”. For carbonate rock, the micrite is in the majority without pure limestone or dolomite.

2.2 Reservoir space type

Nanyishan E32 condensate gas reservoir is classified as an unconventional one where fractures provide the main space for oil and gas. The reservoir is composed of macro-fractures, micro-fractures, inter-crystal pores, and corroded cavities. Micro-fractures and pores are connected by macro-fractures. An intersected and complicated reservoir net is built up which contains a large quantity of hydrocarbon. So, this reservoir is characterized by fractured-cavity system.

2.3 Physical properties of reservoir

2.3.1 Ultra-low porosity

The size and distribution of the porosity are not influenced obviously by the fractures. The porosity ranges 0.9%~11.6%, mainly distributes in 1.5%~4%, and average 3.92%, which indicates porosity of Nanyishan reservoir is ultra-low.

2.3.2 Permeability

Two hundred and fifty-five (255) core samples are gathered from Nanyishan reservoir interval, of which 241 samples do not contain fractures. The permeability of the overwhelming majority of the samples without fracture is lower than 1×10-μm. On the contrary, the permeability of the rock with fractures is higher than 1.32×10-μm, mostly in the range of 10~200×10-μm, and can reach to 6347.13×10-μm. Thus, it is confirmable that the primary flowing passageway for oil and gas in Nanyishan reservoir is supplied by the fractures.

Based on the mercury drainage experiments, in the fractured reservoir interval, the drainage pressure and the saturation mid-value pressure is in the range of 1.3~8.06 MPa and 3.12~10.22 MPa, respectively. In the intervals without fracture, however, the drainage pressure is generally larger than 30MPa and the saturation mid-value pressure is about 80~124 MPa. Besides, according to the fracture characteristics obtained from well testing of Nan6 in Nanyishan

3. Fracture-cavity system identification

3.1 Identification of fracture-cavity system in drilling

Fracture or corroded cavity can be marked by the following four phenomena: circulation loss, well kick, well blowout, and drilling time decreasing. Drilling fluid loss often occurs in drilling process in Nanyishan reservoir, where the more the fractures and cavities are, the more the drilling fluid loses. There are three (3) examples of circulation loss indicating fracture-cavity system:

- (1) 104 drilling fluid were lost in interval 3009~3106m in well Nan6;

- (2) 193. drilling fluid were lost in interval 3021~3317m in well Nan3; and

- (3) 333 drilling fluid were lost in interval 2990~3169m in well Nan9.

3.2 Identification of fracture-cavity system in logging

In the Nanyishan reservoir interval, most of the caliper logs show borehole enlargement occurred and STD logs indicate cycle skip took place obviously in drilling process. Well Nan6 shown the above two characteristics when encountered reservoir interval 3000~3076m, which had the gas and condensate oil productivity of 11.5×/d and /d, respectively. Otherwise, three features, i.e., low electric resistivity low gamma, and low neutron-gamma indicate the distribution of fractures.

4. Characteristics of gas well productivity

4.1 Gas productivity by natural energy is low

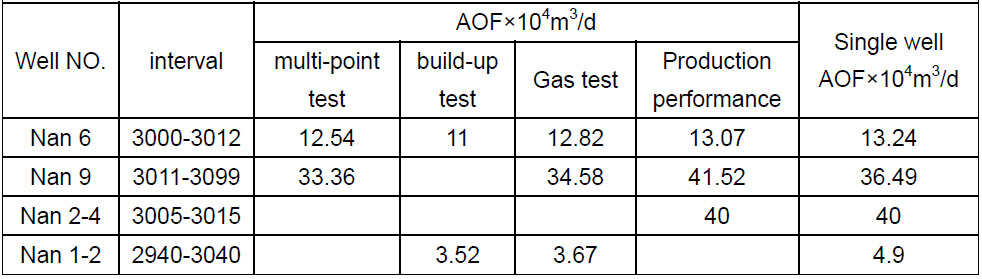

AOF is gathered based on multi-point testing, build-up testing, gas well testing, and production performance data. Single well AOF is defined by the average of AOF shown in Table 1.

The average AOF of gas well in Nanyishan E32 condensate gas reservoir is 236,600m3/d. Well Nan2-4 has the highest productivity of 400,000m3/d (AOF), while well Nan1-2 has the lowest productivity of 49,000m3/d (AOF). Therefore, the gas well productivity by natural energy drive is low.

4.2 Low permeability is the primary reason for low productivity

Well test interpretation (WTI) was run on 3 wells in Nanyishan E32 condensate gas reservoir by modern WTI software. Well Nan6 has the highest permeability and Well Nan 1-1 has the lowest permeability. The effective permeability of the two wells is 0.145×10-3μm2 and 0.011×10-3μm2, respectively. The average permeability of this gas reservoir is 0.058×10-3μm2, which means the reservoir is ultra-low permeable and compacted.

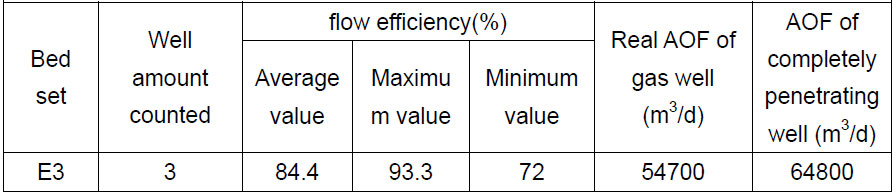

Pollution analysis of this condensate gas reservoir is shown in Table 2, which states the average flow efficiency of gas well is 84.4%. The productivity can rise up 15.6% if the pollution is cleared up. Therefore,the pollution of gas well was not serious.

The influencing factors of gas productivity are effective thickness, permeability, gas viscosity, Z-factor, pollution coefficient, and so on. The additional flow resistance induced by contamination in Nanyishan E32 condensate gas reservoir is very small, based on well test analysis, which made the output drop 15.6%. So, the low permeability is the essential reason for the low productivity by natural energy drive.

5. The Results

- Nanyishan reservoir is a mixture of carbonate rock, calcareous mudstone, and clastic rock, which has the characteristic of dry inland lacustrine facies of Chaidamu Basin. In structure, the rock is composed by coarse particles mingled with the fine ones. In composition, the rock contains several mineral components. Because of the complexity of the lithology, the rock bears stresses unevenly in the process of diagenesis and tectonic movement. Thus, fractures are generated easily to release crustal stress. The above reasons may contribute to the particularity of Nanyishan reservoir.

- There are macroscopic fractures, microscopic fractures, intercrystal pores, and corroded cavities in Nanyishan reservoir bed. Microscopic fractures and intercrystal pores are connected by macroscopic fractures, which supply the main reservoir space for oil and gas. Nanyishan reservoir is featured by fractured-cavity system.

- Nanyishan reservoir in Chaidumu Basin has dual characteristics. Well blowout and circulation loss occur during drilling process and hole enlargement and cycle skip are shown in electric logging curve, which is the characteristics of fractured limestone reservoir; the reservoir also shows electric logging characteristic of clasolite reservoir, such as negative anomaly of SP.

- Gas well productivity by natural energy drive is low, the essential reason for which is the low permeability of Nanyishan reservoir.

Tables

Table 1 - AOF of Production Well

Table 2 - Pollution Analysis

AAPG Search and Discovery Article #90135©2011 AAPG International Conference and Exhibition, Milan, Italy, 23-26 October 2011.